In the ever-evolving landscape of robotics and automation, one key player stands out – the robotic gripper. This guide delves into the intricacies of robotic grippers, exploring their evolution, types, advanced features, real-world applications, challenges, and future trends. Let’s embark on a journey to understand how these intelligent devices are shaping the future of automation.

Understanding Robotic Grippers

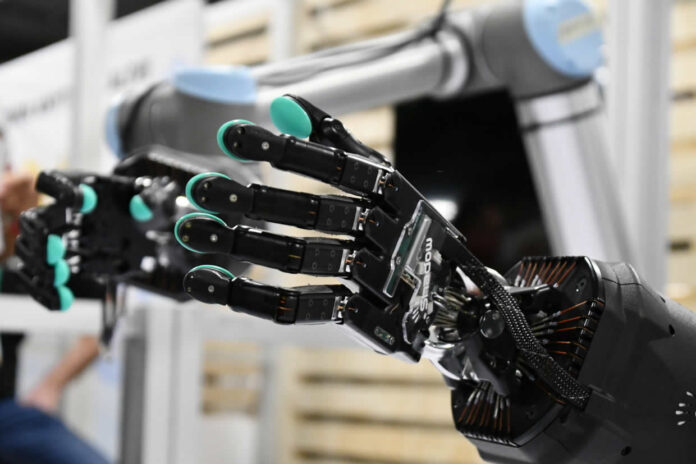

So, what is a gripper? Robotic grippers serve as the hands of robots, playing a pivotal role in automation by enabling machines to grasp, manipulate, and handle various objects. These devices have evolved significantly, transitioning from traditional mechanical grippers to smart and adaptive counterparts.

The anatomy of robotic grippers involves various components and mechanisms. Different types of grippers, ranging from parallel and angular to three-finger variants, utilise materials like metals and polymers, along with advanced sensing technologies, to enhance grip control.

Types of Robotic Grippers

Parallel grippers are characterised by their simple yet effective design, featuring two parallel jaws that move simultaneously to grip objects. Widely used in industrial settings, these grippers offer advantages in terms of simplicity, reliability, and ease of integration.

Angular grippers, with their angular motion capabilities, find applications in scenarios where parallel grippers may face limitations. Their ability to handle irregularly shaped objects and adapt to various orientations makes them valuable in diverse industrial settings.

Three-finger grippers mimic the dexterity of human fingers, providing a versatile solution for handling objects of varying shapes and sizes. These grippers excel in precision tasks, offering accuracy and adaptability across different applications.

Advanced Features in Robotic Grippers

Adaptive grippers represent a leap forward in gripper technology. These grippers can adapt to the shape and size of objects, making them highly versatile in dynamic environments. Their flexibility allows them to handle objects with varying geometries seamlessly. The integration of artificial intelligence (AI) in gripper technology leads to the development of smart grippers. These grippers can learn and adapt to different objects and environments, making real-time decisions to optimise their grip based on changing conditions.

Soft grippers, inspired by soft robotics principles, are designed to handle delicate objects. Their compliance and gentle touch make them suitable for applications in industries like food and electronics, where precision and care are paramount.

Real-world Applications

Robotic grippers play a crucial role in the manufacturing industry, especially in precision assembly tasks. Whether it’s assembling intricate electronic components or handling parts on an automotive assembly line, grippers contribute to increased efficiency and accuracy.

In logistics and warehousing, robotic grippers streamline material handling processes. Palletizing, order fulfilment, and sorting tasks benefit from the speed, accuracy, and reliability of grippers, contributing to enhanced efficiency in supply chain operations.

The healthcare sector leverages robotic grippers for delicate tasks in surgical robotics. From suturing to handling sensitive instruments, these grippers ensure precision and stability, making them indispensable in minimally invasive procedures.

Challenges and Innovations

Challenges in robotic gripper integration include handling objects of diverse shapes and sizes, adapting to varied environmental conditions, and ensuring safety in collaborative workspaces. Innovations in sensing technologies and control mechanisms address these challenges.

Emerging technologies in gripper sensing and control aim to address limitations. These innovations include advancements in lightweight and durable materials, biomechanically inspired designs, and collaborative efforts with human-robot interaction to enhance overall gripper performance.

Considerations for Choosing Robotic Grippers

Choosing the right gripper involves considering industry-specific requirements. Tailoring gripper solutions to unique applications ensures optimal performance and adaptability in diverse environments.

Seamless integration between grippers and other robotic components is essential for overall system efficiency. Collaboration between grippers and robot arms, communication protocols, and compatibility contribute to enhanced performance.

Considering scalability and future-proofing is vital for businesses making long-term investments in gripper technology. Choosing solutions that can adapt to evolving technological trends and scale with growing operational needs ensures sustainability and enduring automation strategies.

Future Trends and Developments

Advancements in lightweight and durable materials, along with biomechanically inspired gripper designs, represent future trends. These innovations have the potential to impact various industries, enhancing the capabilities of robotic grippers.

The integration of robotic grippers with Industry 4.0 technologies, such as smart manufacturing and data-driven analytics, signifies the next phase in automation. Predictive maintenance, real-time monitoring, and data-driven decision-making are set to redefine the landscape of gripper systems.

As automation advances, ethical considerations become crucial. Ensuring ethical use in human-robot collaboration, maintaining transparency in automated decision-making processes, and addressing concerns about job displacement are essential aspects of responsible gripper technology implementations.

Conclusion

In conclusion, this in-depth guide has unveiled the multifaceted world of robotic grippers. From their evolution and diverse types to advanced features, real-world applications, and future trends, robotic grippers are driving the transformation of automation. As industries continue to grasp the potential of these intelligent devices, the synergy between human ingenuity and gripper technology opens doors to a future where precision, efficiency, and adaptability redefine the very fabric of robotics and automation.